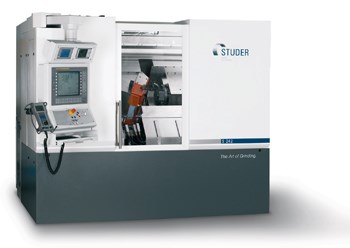

Studer S31 Universal Cylindrical Grinding Machine

Studer S31

Studer S31

-->

The S31 is designed for the grinding of workpieces in individual as well

as small and large series production operations. It can be automated and

is - thanks to its universality - especially suitable for use in the

tooling and aerospace sectors, for example.

Centre height 175 mm (6.9"), Centre distance 1000mm (39.4")

Features:

Distance between

centres of 650

(25.6") or 1000 mm (39.4")

Revolving

wheelhead that can be swivelled manually or automatically

High-resolution B

axis

Frequency-controlled motor grinding spindle for external and

internal grinding

C-axis for the

workhead for form and thread grinding

Selection of

several workhead models available for different grinding jobs

Full enclosure

with 2 sliding doors

Machine base made

of Granitan

Standardised

interface for loader and peripheral devices

Extensive range of

accessories

Specifications:

Grinding length

26/40"

Center height

7"

Workpiece weight

176/264lbs.

Swivel range

wheelhead

-15 to +195°

Grinding wheel

dimensions

20" x 3"

Spindle drive

10 hp

Studer S31cnc Universal Cylindrical

Grinder with ID and OD Grinding Spindles

S31 cnc Offers Large Capacity, Proven Precision and Flexibility

Modular design for quick setup and changeover, state-of-the-art digital

control and drive systems and user-friendly step-by-step programming

make the S31cnc a remarkably flexible solution to a wide variety of

internal and external cylindrical grinding applications. Center height

is 175 mm. Between-centers grinding length is 650 mm, or 1,000 mm. Wheel

size: 500 mm x 63 mm x 203 mm. Chuck capacity between centers is 130 kg.

A dual wheelhead arrangement presents two external grinding wheels for

rough and finish grinding in the same setup. The two wheels are

diagonally positioned and have independent, programmable spindle drive

systems to fully optimize the grinding process. Another wheelhead

configuration is left/right with internal grinding for universal

applications which allows OD, face and ID grinding in one setup.

The universal turret wheelhead with optional B-axis (fine adjustment to

0.0001 degree) swivels automatically, permitting external, internal and

face grinding of workpieces in a single setup. A serrated 1 degree

resolution Hirth ring coupling automatically maintains orientation from

-15 degrees to +195 degrees, thus providing extreme accuracy and

repeatability for grinding even the smallest tapered angles. An optional

C-axis permits ultra-precise form grinding routines for tooling

(punches, for example) and thread grinding.

S31cnc overview

Digital direct-drive, three-phase servo motors with 40-mm diameter

prestressed, precision ballscrews power the X- and Z-axes Cross slide

X-axis travel is 254 mm at speeds ranging to 5,000 mm/min. Linear

resolution is 0.0001 mm. Distance between slideways is 280 mm. Z-axis

slide travel is 800 mm/26" CD or 1,150 mm/45.3" CD. Speed and linear

resolution are respectively 10,000 mm/min and 0.0001 mm. Z-axis distance

between slideways is 200 mm. V and flat guideways are coated with

abrasion-proof Granitan S200 and provide high vibration dampening and

superior rigidity. Patented guideway design prevents hydrodynamic

effects found in conventional guideways and results in high load-bearing

over the entire machine speed range. The machine base of

Studer-developed Granitan S103 delivers outstanding vibration dampening,

rigidity and strength, as well as excellent chemical stability and

thermal compensation. Grinding spindles are powered by two 7.5 kW motor

and have high-precision roller bearings for precise, high-resistance,

maintenance-free operation. Peripheral speed up to 50 m/sec with

continuous speed control to 3200 RPM. Workpiece spindle, with

high-precision roller bearings, handles grinding between dead centers as

well as live grinding with revolving spindle. Precision control permits

fine adjustment of cylindricity during grinding operations to +/- 40 �m.

Guaranteed tolerance precision: 0.0004 mm on roundness and 0.0025 mm

straightness deviation over a length of 650 mm (straightness deviation

of 1,000 mm).

Dressing

Wheel dressing intervals may be made by the operator following these

simple methods: by pressing a pushbutton at any time during any grinding

cycle; after a programmed number of specific machined parts or grinding

operations; at programmed switchover points; at the programmed nominal

size; after a specific number of strokes - or a combination of these,

permitting the optimum solution for the specific grinding application.

Grinding wheel reference points are referred to as "T" numbers, and

together with Studer grinding cycles, "T" numbers permit programming

with nominal size. The actual value indication on the control LCD refers

in each case to the programmed wheel reference point. Values of the

grinding wheel shape are entered in a dressing dialog display at the

control.

Control & programming

The S31cnc features state-of-the-art Fanuc 16i digital control and axis

drive components - or optional Fanuc 21i, a more cost-effective solution

for less demanding applications. Machine operation, setup, changeover,

dressing and programming of even complex parts are easily accomplished

through the innovative, step-by-step Studer Pictogramming which allows

operators simply to connect grinding cycles to one another and add

necessary numerical values. The control then generates the machine

program automatically. Advanced manual programming in G code is of

course also possible. Programming is done directly at the machine or

off-line and then downloaded to the machine control. Process parameters

can be changed on the fly, while the machine runs, without affecting the

workpiece program. The S31cnc control package features proven

application-specific Studer grinding cycles for diameters, shoulders

(left and right), tapers (negative and positive), contours, forms and

threads.

Visit

Grinding.com and Studer