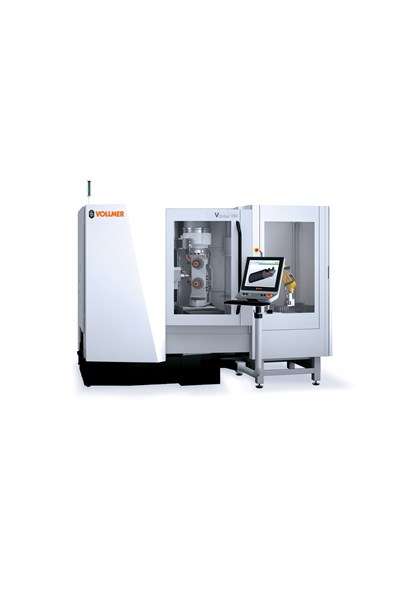

Vollmer CM 200

Those who want to produce accurate metal cutting saw blades must not only pay attention to basic parameters, such as accuracy of the saw blade hole and the appropriate clamping system, they must also ensure that the process is as stable as possible and that the sharpening machine has a high level of rigidity. We have succeeded in meeting these requirements with the unique machine concept of the CM 200. With its fixed grinding unit and solid structure, it offers the highest accuracy in machining tooth faces and tooth tops on metal cutting saw blades. The result: Exact surface quality which pays dividends – for each and every grinding process. The familiar VOLLMER user interface guarantees maximum operating convenience, quick familiarization of the operating staff and efficient operation of the machine. A wide variety of tooth shapes offers a high level of flexibility for the production of metal-cutting circular saws. At the same time, the machine's convenient programming reduces t he setup time.

| Machine Operation: | CNC |

|---|---|

| Grinder Type: | Tool & Cutter |

| Grinding Depth: | 0.630" 16.000mm |

|---|---|

| Grinding Depth Opt: | 7.870" 200.000mm |

| OD Min Grinding Diameter(s): | 7.870" 200.000mm |

| OD Max Grinding Diameter(s): | 33.070" 840.000mm |

| Grinding Wheel: |

|

||||

|---|---|---|---|---|---|

| Regulating Wheel: |

|

IS THIS YOUR COMPANY?