Giuliani F2F

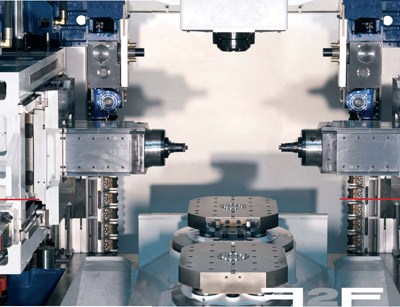

Giuliani F2F Two Spindle Horizontal Machining Center The F2F machine sets a new standard within the machine tool industry by offering one machine base with 2 independent spindles. This concept provides both the flexibility of a machining center but with double the production output at half the fixture cost. The F2F maintains some features that are standard on horizontal single-spindle centers, such as easy set up, accuracy, reliability and palletized fixtures but the fixture costs, are cut in half due to the double spindle concept. The F2F machine has an accessibility, flexibility, precision and number of available tools higher than other double-spindle machining centers that are presently available on the market which allows to reach an higher productivity.

| Machine Type: | Machining Center |

|---|---|

| Num. of Axes: | 7 |

| Operation Type: | CNC |

| CNC Brand: | Fanuc 31i |

| CNC Brand Opt: |

| Table Size L x W (in.): | 15.700(L) x 15.700(W) |

|---|---|

| Table Size L x W (in.) Opt: | 19.700(L) x 19.700(W) |

| Max Workpiece Weight (lbs): | 1,540 |

| Direction: | Horizontal |

|---|---|

| Taper: | HSK 63 |

| Taper Opt: | |

| Top RPM: | 10,000 |

| Top RPM Opt: | 16,000 |

| HP (30 min rating): | 53.00 |

| Tool Carrier: | Arm-Type ATC |

|---|---|

| Num. Tools: | 240 |

| Tool Change Time (sec): | 1.30 |

| Pallet Changer Available: | Standard |

| Num. Pallets: | 2 |

| Num. Axes: | 7 | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| U Axis: | None | ||||||||||||||||||||||

|

|||||||||||||||||||||||

IS THIS YOUR COMPANY?