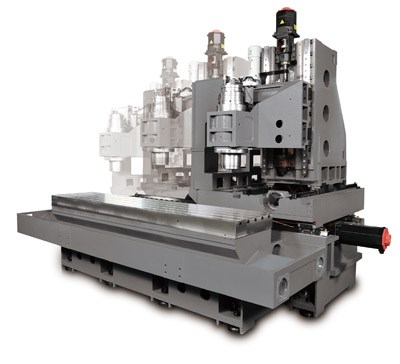

YCM TCV2000A

Travel Column Structure Design to Increase Machining Efficiency ▲Fixed work table ensures the best possible dynamic leveling. ▲Fixed work table eliminates parts movement on the axial and greatly improves precision. ▲Rigid and fixed table allows extra weight capacity. ▲Extra large table can be divided into dual working envelopes for easy setup and machining flexibilities. High Rigid, High Speed X/Y/Z Rapid Axial Movement ▲ Maximum 0.8g axial acceleration(X:0.5g, Y:0.8g, Z:0.8g) greatly increases machining efficiency. ▲All 3 axes are equipped with high rigidity roller type guideways, extra large diameter precision ball screws, and direct coupled axial motors to achieve ultra high speed and rigidity. ▲Circulated sleeve cooling system is installed in X-axis ball screw to ensure the stable accuracy over long periods of operation.

| Machine Type: | Machining Center |

|---|---|

| Num. of Axes: | 3 |

| Operation Type: | CNC |

| CNC Brand: | HEIDENHAIN iTNC-530 Control |

| Table Size L x W (in.): | 98.400(L) x 20.470(W) |

|---|---|

| Max Workpiece Weight (lbs): | 4,400 |

| Support Index Table: | None |

| Support Rotary Table: | None |

| Direction: | Vertical |

|---|---|

| Taper: | BBT40 |

| Top RPM: | 12,000 |

| Top RPM Opt: | 15,000 |

| HP (30 min rating): | 29.30 |

| U Axis: | None |

| Tool Carrier: | ATC |

|---|---|

| Num. Tools: | 30 |

| Num. Tools Opt: | 40 |

| Pallet Changer Available: | None |

| Num. Axes: | 3 | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| U Axis: | None | ||||||||||||||||||

|

|||||||||||||||||||

IS THIS YOUR COMPANY?

- 300.jpg;width=300)

- 300.jpg;maxWidth=130)