Danobat TCN-18-2T

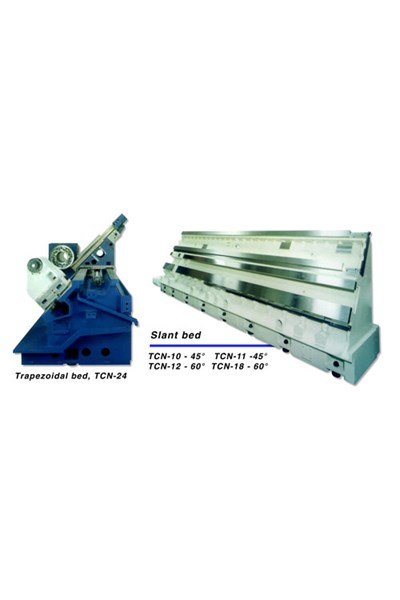

Danobat TCN-18-2T Series Universal Lathe Danobat Flexible, Accurate TCN-18-2T Series Universal CNC Horizontal Lathes In the TCN-18-2T there is an upper second turret and tailstock has been replaced by a sub-spindle wich is synchronised with the main one. Each turret work at its own spindle. Therefore it is a fit machine for parts requiring on both faces or ends machining at the same time or for machining in one shift those pieces that of another form would need two phases of mechanizing. As one of the headstocks is movable, no operator intervention is necessary, and the part is finished automatically. Commonly, the part is automatically loaded by means of a bar advance, gantry, robot or box magazine, and is also unloaded automatically using a part clamp, robot or gantry The TCN Universal CNC Horizontal Lathes feature a one-piece heavily ribbed bed cast of Meehanite, ground and hardened guideways and telescopic metal covers that protect guidew ays from chips that could cause damage. The 45 degree - 60 degree slant bed design minimizes cutting force and provides exceptional rigidity for precision, heavy cuts. Tooling is easily accessible for fast setup and part loading and unloading can be done quickly and easily with less operator fatigue. The TCN uses sub-spindles and features a Y-axis that provides the flexibility to machine complex parts with a single setup. The TCN can also be easily automated and is available with customized loading and unloading systems.

| Machine Style(s): | Universal |

|---|---|

| Spindle Direction: | Horizontal |

| Operation Type: | CNC |

| CNC Type: | Siemens 840 D |

| CNC Type Opt: | Fanuc 18 ITB |

| Main Spindle Turning Diameter Max: | 16.690" |

|---|---|

| Main Spindle Turning Length Max: | 118.000" |

| Main Spindle Chuck Diameter: | 15.750" |

| Main Spindle Max Swing: | 31.500 |

| Main Spindle Bar Diameter Max: | 5.510" |

| Tail Stock Quill And Body: | Standard |

| Num. Main Spindles: | 1 | |||||

|---|---|---|---|---|---|---|

| Main Spindle 1: |

|

|||||

| Main Spindle 2: |

|

| Primary Tool Carrier: | Turret | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Max Tools: |

|

||||||||

| Num. Simultaneous Cutting Tools: | 2 | ||||||||

| Num. Simultaneous Cutting Tools Opt: | 3 | ||||||||

| Secondary Mill/Drill Function: |

|

| Number Of Axes: | 4 | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number Of Axes Opt: | 5 | ||||||||||||||||||

| Number Of Axes Opt 2: | 5 | ||||||||||||||||||

|

|||||||||||||||||||

IS THIS YOUR COMPANY?