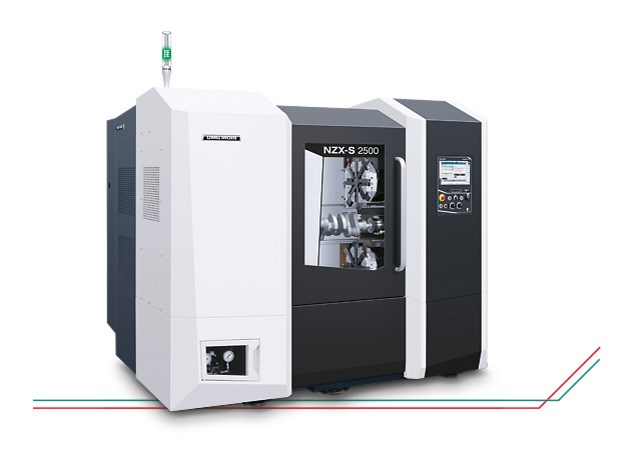

DMG MORI USA, Inc. NZX-S 2500

Optimal design for shaft machining Greater productivity per unit area with compact design and reduced foot print A light but rigid body achieved through FEM analysis Symmetrical structure in relation to the spindle controls Thermal displacement, ensuring improved accuracy in continuous machining Excellent access to the workpiece and tools, enabling easy setups Better chip disposal thanks to the vertical bed DMGMORI operation system COMPACTline with MAPPS Pro 12.1" multi-touch screen offers innovative functions and maximum operating comfort

| Machine Style(s): | Bar, Chucker |

|---|---|

| Spindle Direction: | Horizontal |

| Operation Type: | CNC |

| CNC Type: | MAPPS |

| Main Spindle Turning Diameter Max: | 7.900" |

|---|---|

| Main Spindle Turning Length Max: | 27.600" |

| Main Spindle Chuck Diameter: | 0.400" |

| Main Spindle Bar Diameter Max: | 2.000" |

| Tail Stock Quill And Body: | None |

| Num. Main Spindles: | 2 | |||||

|---|---|---|---|---|---|---|

| Main Spindle 1: |

|

|||||

| Main Spindle 2: |

|

| Primary Tool Carrier: | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Max Tools: |

|

||||||||

| Second Tool Carrier: | |||||||||

| Max Tools: |

|

||||||||

| Num. Simultaneous Cutting Tools: | 2 | ||||||||

| Secondary Mill/Drill Function: |

|

| Number Of Axes: | 5 | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|||||||||||||||||||

IS THIS YOUR COMPANY?