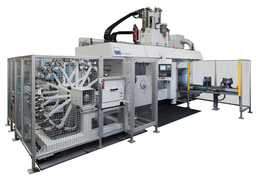

EMAG VL 2 DUO line

The VL 2 modular vertical turning center provides the ideal machine base for the VL 2 DUO line, perfect for the manufacturing of chucked parts up to 100 mm in diameter. The vertical turning centers are interlinked by a TrackMotion automation system, specially developed for EMAG modular machines. To achieve the most compact design for the manufacturing system, the vertical turning centers energy container has been separated from the machine, so that the automation system can be run immediately behind the machining area of the vertical turning centers. The VL 2 DUO provides the user with two vertical turning centers that are perfectly coordinated with the automation system. The result is a high-productivity manufacturing system for chucked parts, combined with the flexibility of individual vertical turning centers. This variable system allows for dynamic further development, and optimum adaptability with regard to varying manufacturing situati ons. The interlinked vertical turning centers in combination with the TrackMotion automation system and a part storage unit that is accordingly equipped, allow high-productivity manufacturing of medium to high-volume series. If required, the entire manufacturing system can be expanded by another modular machine, e.g. the vertical VL 4 H hobbing machine, to create a manufacturing system for gear wheels. The vertical turning center can also be used on its own – the modular design of the vertical turning centers and of the automation system keep all your options open.

| Machine Style(s): | Chucker |

|---|---|

| Spindle Direction: | Vertical |

| Operation Type: | CNC |

| Main Spindle Chuck Diameter: | 6.500" |

|---|---|

| Tail Stock Quill And Body: | None |

| Num. Main Spindles: | 1 | |||||

|---|---|---|---|---|---|---|

| Main Spindle 1: |

|

|||||

| Main Spindle 2: |

|

| Primary Tool Carrier: | Turret | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Max Tools: |

|

||||||||

| Num. Simultaneous Cutting Tools: | 1 | ||||||||

| Secondary Mill/Drill Function: |

|

| Number Of Axes: | 3 | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|||||||||||||||||||

IS THIS YOUR COMPANY?