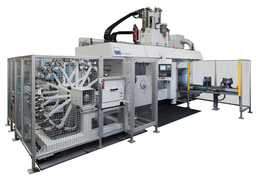

EMAG VSC 400 DUO

VSC DUO Multi-Spindle Machine for Medium and Large Batch Production VSC DUO multi-spindle machines have the smallest footprint for the machining of components in first and second operation. The multi-spindle lathes can be used for identical or different machining cycles, as they feature two separate machining areas with independently programmable overhead slides and turrets to streamline sequential operations (OP 10 + OP 20). Both turrets on these multi-spindle machines accommodate not only stationary tools but also driven drilling and milling tools. This allows for either identical or different operations to be carried out on the two work spindles.

| Machine Style(s): | Chucker |

|---|---|

| Spindle Direction: | Vertical |

| Operation Type: | CNC |

| CNC Type: | Fanuc |

| CNC Type Opt: | Siemens |

| Main Spindle Turning Diameter Max: | 13.400" |

|---|---|

| Main Spindle Chuck Diameter: | 12.400" |

| Main Spindle Chuck Diameter Opt: | 15.700" |

| Main Spindle Max Swing: | 16.500 |

| Tail Stock Quill And Body: | Optional |

| Num. Main Spindles: | 1 | |||||

|---|---|---|---|---|---|---|

| Main Spindle 1: |

|

|||||

| Main Spindle 2: |

|

| Primary Tool Carrier: | Disc Type Turret | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Max Tools: |

|

||||||||

| Rotary Tool: |

|

||||||||

| Num. Simultaneous Cutting Tools: | 1 | ||||||||

| Secondary Mill/Drill Function: |

|

| Number Of Axes: | 2 | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|||||||||||||||||||

IS THIS YOUR COMPANY?