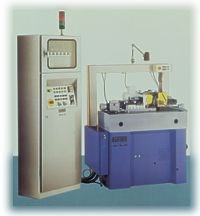

Agathon 400 PENTA

Agathon 400 PENTA Insert Grinder with 5 Axes 400 PENTA Insert Grinder Different insert clamping systems enable automatic grinding of all indexable inserts and grooving tools that have relief on all sides, while maintaining tightest tolerances. Shortest possible job changes between anvil insert and insert tool holder clamping methods make the 400 PENTA highly versatile. The new machine concept guarantees maximum flexibility with the utilization of 3 rotational and 2 linear axes. Even the most demanding insert geometries can be programmed quickly and efficiently with Agathon-developed software. The 400 PENTA 5-axis insert grinder is a fully automatic grinding center of the latest generation providing increased efficiency for insert production. Principal design features: New axes-concept with a 5th axis (A axis) Grooving inserts, Threading inserts, Cut-off inserts, Ball-nose inserts and other geometries Fastest transfer movements by means of linear and torque motors Optimized movements of axes and collision control by means ofnewest software Centrifuge (Turbo separator) Digital drives Process optimization through new dressing possibilities (patent pending) Remote fault finding via Internet Vision System integrated in the loading robot head Flexible clamping systems Data administration in SQL data base Technical data: Working capacity smallest inscribed circle diameter 4.76mm (0.187") largest circumscribed circle diameter 98mm (3.858") Operative travel of A axis (B1) -22° to +28° Operative travel of A axis (B3) -22° to +202° Clearance angle -97° to +100° Grinding wheel DIA 400mm (15.748") Cutting speed 12 to 63m/s (2'350 to 12'400ft/min) Power consumption 23KVA (without options) Weight approx. 6500kg

| Machine Operation: | CNC |

|---|---|

| Grinder Type: | Tool & Cutter |

| OD Min Grinding Diameter(s): | 0.190" 4.750mm |

|---|---|

| OD Max Grinding Diameter(s): | 3.860" 97.990mm |

| Grinding Wheel: |

|

||||

|---|---|---|---|---|---|

| Wheel Head: |

|

IS THIS YOUR COMPANY?