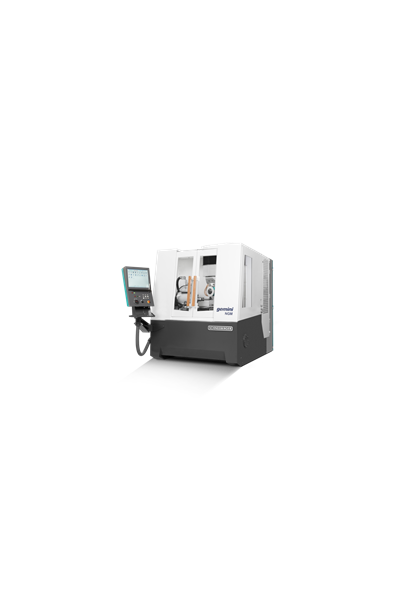

Schneeberger gemini NGM GHP

The highly dynamic 6-axis CNC grinding machine for relief grinding of hob cutters. ThegeminiGHPis the highly dynamic 6-axis CNC grinding machine for the profile back off grinding of hob cutters. Maximum precision is guaranteed with a total of 6 CNC axes, hydrostatic guides with linear and torque motor technology. The oscillating grinding process is the heart of the system for generating precision back off grinding. Thanks to interchangeable grinding heads, with and without support center, grinding wheels with diameters of between 26 and 100 mm can be used. The high-performance control system processes precise way points along the back off grinding curve, low moving masses and modern linear motors guarantee very high dynamics. The set-up for new tools is supported through a direct graphical operator interface on the machine and is very efficient and user-friendly. Production:gear hob profile, any profile according to standard or special Material: HSS or carbide Diameter: up to 200 mm Spiral angle: +/- 45° Length: up to 250 mm Numerous accessories for the application spectrum and increased productivity: Dressing unit for dressing profiles Manual or hydraulic tailstock Synchronous pawl system and clamping mandrel Coolant filtration system Exhaust air filter CO2 extinguishing system

| Machine Operation: | CNC |

|---|---|

| Grinder Type: | Profile |

| CNC Model: | Fanuc 31i-B5 |

| Grinding Length: | 9.840" 250.000mm |

|---|---|

| OD Max Grinding Diameter(s): | 7.870" 200.000mm |

| Grinding Wheel: |

|

||||||

|---|---|---|---|---|---|---|---|

| Wheel Head: |

|

| Longitudinal: | 15.750" 400.000mm |

|---|---|

| Cross: | 15.750" 400.000mm |

| Vertical: | 14.950" 380.000mm |

IS THIS YOUR COMPANY?