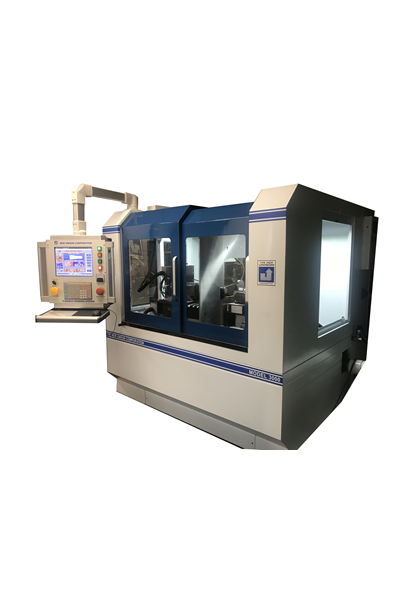

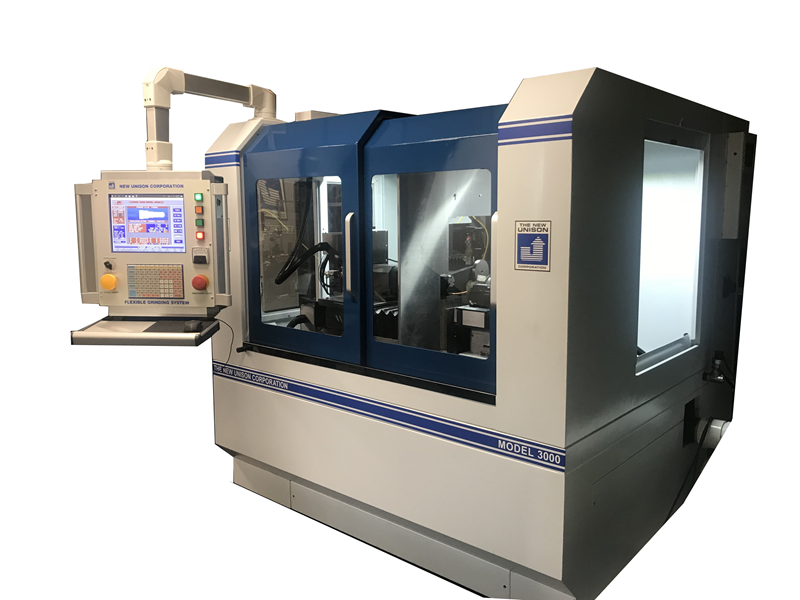

Unison Corp. Model 3000

The Model 3000 is designed for tool blank preparation and can rough & finish grind in one pass with its powerful 9,000 RPM and 10,000 RPM direct drive spindles. This grinder features Yaskawa AC Drive Amplifiers and Servomotors as well as an Automatic Pick-n-Place Parts Loader/Unloader for continuous grinding of parts. The Model 3000 is equipped with a Schaublin W25 Pneumatic Workholding System and a precise probe assembly to guarantee repeatability of parts. The Model 3000 is built on a polymer cast base and can be equipped with an on-board electric wheel dressing system to automatically dress the finishing wheel. The Model 3000 features Unison's new EZ Software allowing the machine's operator to quickly customize and/or modify tool geometry with a user friendly interface by merely "filling in blanks" and then verifying the part program by using the machine's real-time 3D Parts Predictor. Each machine is supplied with a complete software package and library of tool programs at no ad ditional charge. The Model 3000's Computer Control monitors critical machine functions and alerts the operator to problems encountered during grinding as well as errors are tracked and logged within the Control to help identify problems. The Model 3000 can be networked and/or monitored via the internet and can be equipped with a Remote Connect feature allowing direct communication with Unison.

| Machine Operation: | CNC |

|---|

| OD Min Grinding Diameter(s): | 0.010" 0.300mm |

|---|---|

| OD Max Grinding Diameter(s): | 1.000" 25.400mm |

| Wheel Head: |

|

||

|---|---|---|---|

| Workhead: |

|

| Longitudinal: | 14.130" 358.780mm |

|---|---|

| Cross: | 1.200" 30.480mm |

IS THIS YOUR COMPANY?