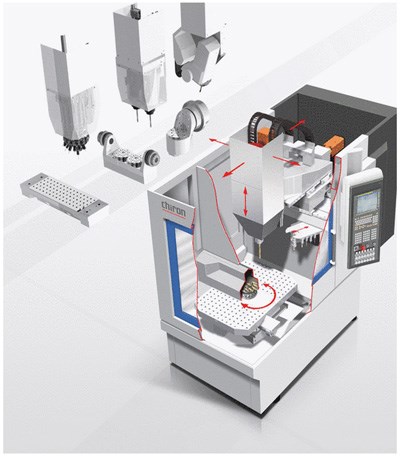

Chiron MC 326

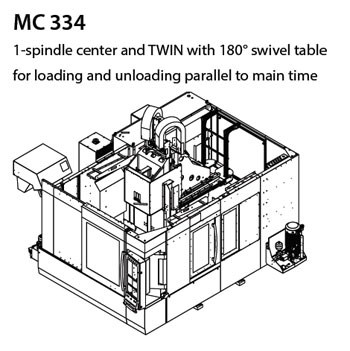

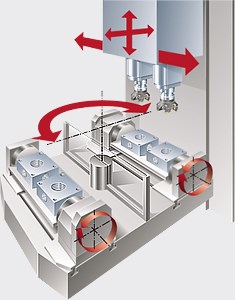

System 3 Vertical machining centers with 180 degree swivel table The System 3 centers are two-place centers (two separate work spaces for parallel loading and unloading) with one or two (TWIN) working spindles. Designed as TWIN center for highly productive serial productions � high-performing, flexible and robust. Automation-compatible machine design for any type of workpiece handling via robots or pallet changing system and loading portal. Suitable for dry and wet machining with coolant pressure up to 100 bar. Twin Technology Synchronous manufacture of 2 workpieces in one work cycle automatically doubles productivity Machining 4 workpieces with 2 spindles guarantees at least a 30% reduction of item costs TWIN spindle 5-axis machining results in maximum quality for complex parts in series production Reliable technology for turnkey solutions with integrated and external automation 4 spindle distances for various parts sizes individually available on all one-place and two-place TWIN centers

| Machine Type: | Boring Mill Machining Center |

|---|---|

| Num. of Axes: | 3 |

| Operation Type: | CNC |

| CNC Brand: | Fanuc 31 i-A5 |

| CNC Brand Opt: | Siemens 840 D sl |

| Table Size L x W (in.): | 27.500(L) x 15.700(W) |

|---|---|

| Table Size L x W (in.) Opt: | 43.300(L) x 19.490(W) |

| Max Workpiece Weight (lbs): | 880 |

| Support Index Table: | Standard |

| Support Rotary Table: | Optional |

| Num. Main Spindles: | 2 |

|---|---|

| Direction: | Vertical |

| Taper: | HSK-A63 |

| Top RPM: | 10,500 |

| Top RPM Opt: | 12,000 |

| HP (30 min rating): | 49.00 |

| U Axis: | None |

| Tool Carrier: | ATC |

|---|---|

| Num. Tools: | 48 |

| Num. Tools Opt: | 60 |

| Tool Change Chip Time (sec): | 2.40 |

| Pallet Changer Available: | None |

| Num. Axes: | 3 | ||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Num. Axes Opt: | 4 | ||||||||||||||||||||||||||

| U Axis: | None | ||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||

IS THIS YOUR COMPANY?