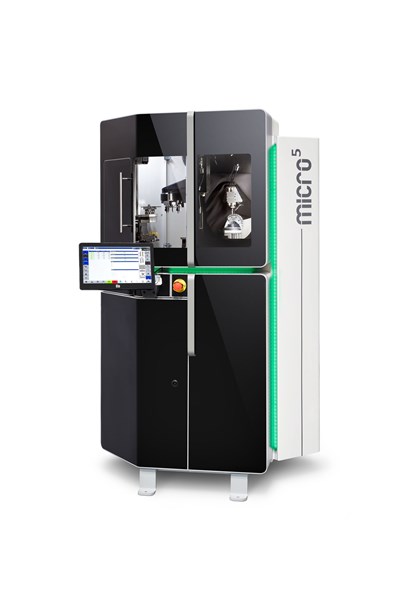

Chiron Series 22

The CHIRON 22 Series convincingly addresses the current requirements on precision, dynamics and high technical availability in the complete machining of large-volume components such as electric motor and transmission housings, oil sumps and chassis components. The foundation for this is a machine platform with a mobile gantry design. This significantly increases rigidity for even more precise machining results. Using the DZ 22 W five axis with workpiece changer and a spindle distance of 600 mm, two different main spindles can be operated, depending on the task at hand: the high-speed spindle for workpieces made from aluminum or aluminum alloys, and the high-torque spindle for hard-to-machine materials and large tools. The series also includes configurations for direct loading and a HSK-A100 interface.

| Machine Type: | Machining Center |

|---|---|

| Num. of Axes: | 3 |

| Operation Type: | CNC |

| CNC Brand: | Fanuc |

| CNC Brand Opt: | Siemens |

| Support Index Table: | Optional |

|---|---|

| Support Rotary Table: | Optional |

| Num. Main Spindles: | 2 |

|---|---|

| Direction: | Vertical |

| Taper: | HSK 63A |

| Taper Opt: | HSK 100A |

| Top RPM: | 20,000 |

| Top RPM Opt: | 12,500 |

| U Axis: | None |

| Tool Carrier: | ATC |

|---|---|

| Num. Tools: | 77 |

| Num. Tools Opt: | 210 |

| Tool Change Time (sec): | 1.00 |

| Tool Change Chip Time (sec): | 2.70 |

| Pallet Changer Available: | Optional |

| Num. Pallets: | 2 |

| Num. Axes: | 3 | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Num. Axes Opt: | 4 | ||||||||||||||||||

| U Axis: | None | ||||||||||||||||||

|

|||||||||||||||||||

IS THIS YOUR COMPANY?