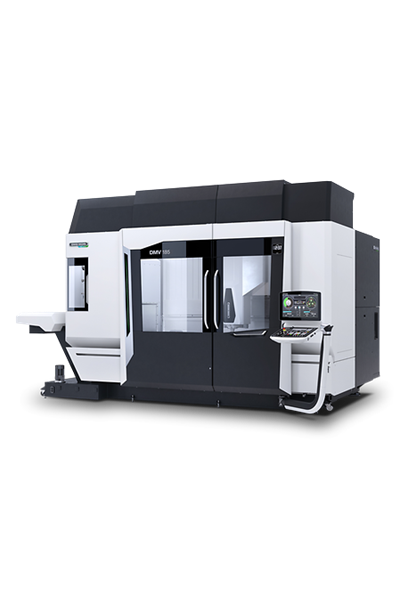

DMG MORI USA, Inc. NVX 5100 2nd Generation

Super-wide slideways (X- / Y-axis) to minimize quadrant projection High-rigidity roller guides (Z-axis) Optimized column shape substantially reduces thermal displacement Coolant tank for collecting casting sludge (option) Through-spindle coolant system (unit on coolant tank) Chip conveyor (internal, spiral type) Accessibility -excellent access to the table and a wide door opening Loading and unloading with a crane - the ceiling part also opens By changing the spindle unit t World’s Best Spindle Technology No. 40 taper spindle achieves outstanding high-speed machining (speedMASTER) Stable high-accuracy machining made possible by drastically improved spindle run-out accuracy (speedMASTER) No. 50 taper spindle achieves outstanding heavy-duty cutting (powerMASTER) Thermal expansion compensation by spindle growth sensor (powerMASTER) o a complete unit, which also includes the rear bearing units, we were able to reduce the spindle replacement time.

| Machine Type: | Machining Center |

|---|---|

| Num. of Axes: | 3 |

| Operation Type: | CNC |

| CNC Brand: | CELOS and Industry 4.0 |

| CNC Brand Opt: | CELOS with MAPPS V |

| Table Size L x W (in.): | 53.100(L) x 23.600(W) |

|---|---|

| Max Workpiece Weight (lbs): | 2,646 |

| Support Index Table: | Optional |

| Support Rotary Table: | Optional |

| Direction: | Vertical |

|---|---|

| Top RPM: | 15,000 |

| Top RPM Opt: | 20,000 |

| HP (30 min rating): | 34.90 |

| U Axis: | None |

| Tool Carrier: | ATC |

|---|---|

| Num. Tools: | 30 |

| Num. Tools Opt: | 90 |

| Pallet Changer Available: | Optional |

| Num. Axes: | 3 | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Num. Axes Opt: | 4 | ||||||||||||||||||

| U Axis: | None | ||||||||||||||||||

|

|||||||||||||||||||

IS THIS YOUR COMPANY?