Fives Cincinnati PMT

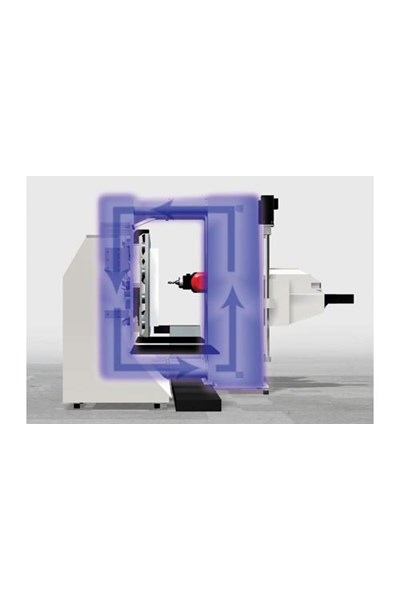

Gantry Model Precision Mill and Trim (PMT) offers speed, accuracy and performance to manufacturers producing large parts from fiberglass, graphite composite, aluminum, and non-ferrous alloys. The machine is built on a rugged rail-type vertical gantry platform of standard modules, the PMT offers unlimited X-axis range, up to 60 m/min traverse speed, to perform precise 5-axis and 5-side maneuvering for milling, trimming, drilling and cutout operations. The PMT is a modular and highly configurable system to provide the right combination of features for most applications. Utilizing a rail-type gantry design, the machinehandle extremely long parts or enablemultiple workzone part processing. As options, the Z-axis can be configured to provide 1, 1.5 and 2 m ram travel. The Y-axis cross rail can be configured to provide from 2 to 6 meters travel. The XYZ axes feature linear ways and AC servomotor rack-and-pinion drive systems. The two-axis spindle head provides 5-sided and 5-axis capabilities. A variety of workholding systems are available as option to meet specific application needs.

| Machine Type: | Machining Center |

|---|---|

| Num. of Axes: | 5 |

| Operation Type: | CNC |

| CNC Brand: | Siemens 840D |

| CNC Brand Opt: | Fanuc 31i |

| Table Size L x W (in.): | 78.000(L) x 78.000(W) |

|---|---|

| Table Size L x W (in.) Opt: | 99999.000(L) x 157.000(W) |

| Max Workpiece Weight (lbs): | 999,999 |

| Support Index Table: | None |

| Support Rotary Table: | None |

| Direction: | Vertical |

|---|---|

| Taper: | HSK A63 |

| Top RPM: | 24,000 |

| Top RPM Opt: | 30,000 |

| HP (30 min rating): | 27.00 |

| HP Opt: | 45.00 |

| U Axis: | None |

| Tool Carrier: | 24 |

|---|---|

| Num. Tools: | 48 |

| Pallet Changer Available: | None |

| Num. Axes: | 5 | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| U Axis: | None | ||||||||||||||||||||||

|

|||||||||||||||||||||||

IS THIS YOUR COMPANY?