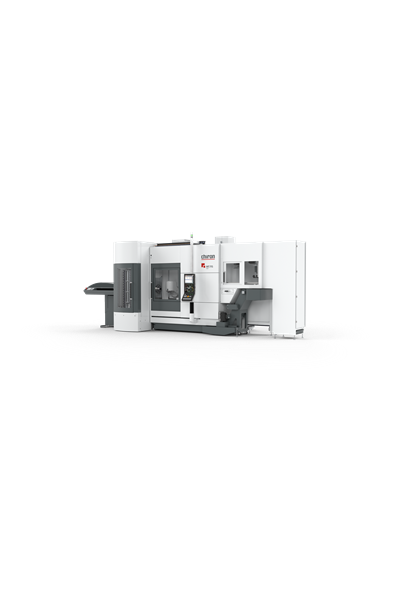

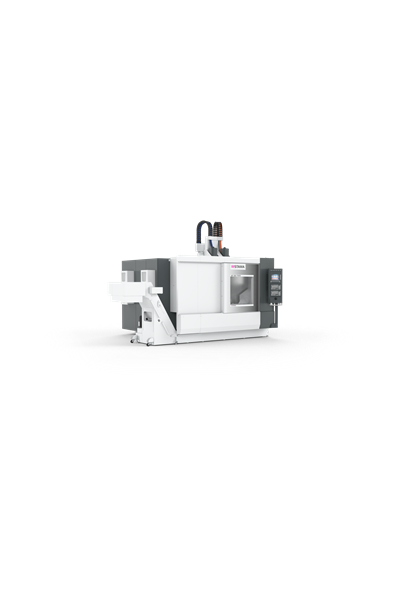

Chiron MT 715 Two

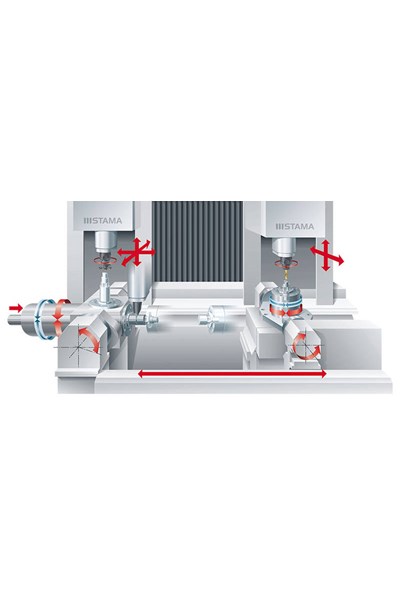

5-axis complete machining, milling-turning operations in any sequence on six sides, workpiece dimensions up to a diameter of 300 mm and a length of 1,000 mm: The 715 Series brings together all of these options into one machine platform. Clear advantages over production spread across several machines: Higher precision, shorter throughput times, more flexibility, minimized set-up times for small batch sizes, and reduced logistics costs. The Series is available in two versions with different expansion levels: MT for Mill Turn, MP for Multi Profile. The optional second machining unit can be used for guide bushes, steady rests, rotating centers, vices, or other turning tools. Integrated workpiece handling provides significantly increased productivity and reduced costs in each machine, with additional unmanned shifts.

| Machine Style(s): | Bar, Chucker |

|---|---|

| Spindle Direction: | Vertical |

| Operation Type: | CNC |

| CNC Type: | Siemens |

| Main Spindle Turning Diameter Max: | 8.270" |

|---|---|

| Main Spindle Turning Length Max: | 15.750" |

| Main Spindle Chuck Diameter: | 13.780" |

| Main Spindle Bar Diameter Max: | 3.940" |

| Sub Spindle Turning Diameter Max: | 3.940" |

| Sub Spindle Turning Length Max: | 9.840" |

| Tail Stock Quill And Body: | Optional |

| Num. Main Spindles: | 2 | |||||

|---|---|---|---|---|---|---|

| Main Spindle 1: |

|

|||||

| Main Spindle 2: |

|

|||||

| Sub Spindle (Standard): |

|

| Primary Tool Carrier: | HSK 63 | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Max Tools: |

|

||||||||

| Num. Simultaneous Cutting Tools: | 2 | ||||||||

| Secondary Mill/Drill Function: |

|

| Number Of Axes: | 5 | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|||||||||||||||||||

IS THIS YOUR COMPANY?