Makino U1310

The U1310 machine delivers speed and precision to large Wire EDM operations. The machine utilizes a stationary work table design with a programmable 3-Sided rise and fall work tank, and can achieve positioning accuracies of +/- 3µm (+/- 0.0001”) over its full stroke. The U1310 supports submerged operations up to 24.4” thick, and incorporates the di-electric reservoir into the base casting of the machine to minimize floor space and to improve thermal stability. The machine is configured with the split V-Guide wire guide system, and is standard with a high capacity 4 filter filtration system, high capacity dual digitally controlled flush pumps, and a high capacity 66 lbs. wire spool system. The U1310 is equipped with the Hyper-i control system, which provides an intuitive user-friendly interface with a large 24” class high definition touch-screen display, and contains advanced help functions that provide the operator with all of the resources necessary to remain highly productive .

| Machine Type: | CNC Wire |

|---|---|

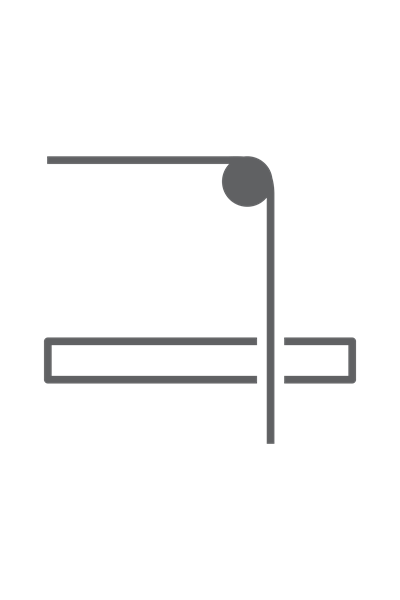

| Frame Type: | Bridge |

| Submersible: | Standard |

| Table (L x D): | 67.700" x 58.100" |

|---|---|

| Worktank (L x D x H): | 79.000" x 63.000" x |

| Max Part Thickness: | 24.410 |

|---|---|

| Max Taper Angle: | 15.0000° |

| Max Taper Angle Opt: | 45.0000° |

| Min Hole Diameter: | 0.0600" |

| Max Wire Diameter: | 0.0100" |

| Auto Rethreading: | Standard |

| Auto Restart After Power Out: | Standard |

| Number Of Axes: | 3 |

|---|---|

| X Axis Travel: | 51.570" |

| Y Axis Travel: | 39.760" |

| Z Axis Travel: | 20.470" |

| U Axis Available: | Standard |

IS THIS YOUR COMPANY?