SODICK Linear Motor Wire EDM Model AG600L

AG600L

Linear Motor Wire EDM

KEY FEATURES

Energy Saving Circuit saves on power consumption

Motion Controller provides simultaneous axis movement &

makes changes to the spark gap in real time

On-board, user-friendly Heart NC software programs 2 & 4

axes shapes and can import CAD files

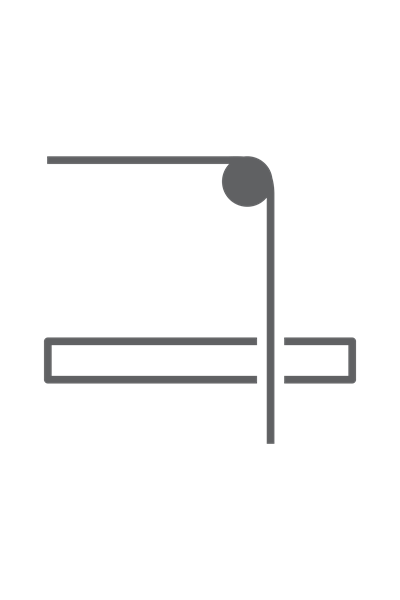

Rise-Fall Worktank provides easy access to work area and is

ideal for automation

Since linear motors will never

wear, they come with a 10 Year Positioning Guarantee

Linear Motor Drives with Absolute Glass Scale Feedback

Sodick's AG600L linear motor driven, high precision wire EDM

features new user-friendly EDMing technology which further

enhances productivity and EDMing precision. The machine's

linear motor axes drives are coupled with .4 millionths

Heidenhain absolute glass scale feedback on the X,Y,U,V axes

which ensure precision cutting and positioning accuracy. With

the new Heidenhain ultra-precision absolute linear glass scales,

the true machine position is always known. This reduces set-up

time since the operator no longer has to home the machine after

it has been powered down. Sodick's X,Y,U,V linear motor drives

will last forever, have no backlash and are backed by Sodick's

10 year positioning accuracy guarantee.

SMART Control Technology

The machine's Windows XP based, high speed control comes

standard with a large 15" LCD touch screen which is easy to view

and eliminates glare. Standard items; such as, the LAN network

connection and a 1GB USB memory stick makes it easy to transfer

programming files. The 4GB compact flash card memory eliminates

hard drivesthat can crash resulting in lost data. In the event

of a power loss, the UPS system will automatically lock the axis

drives. Once power is restored, the machine will automatically

power itself up and resume cutting. The Heart NC on-board,

user-friendly programming software is beneficial for shops that

are on a tight budget. Heart NC can program both 2 and 4 axes

shapes and import CAD files. After programming, the

user-friendly Condition Set Screen will automatically select the

optimum cutting conditions and offsets from its internal

database and adds them to the NC program. The AG400L precision

wire EDM comes with the K-SMC (Sodick Motion Controller) which

provides simultaneous axes movement and makes spark gap changes

in real time. This results in improved machining speed,

workpiece accuracy and fewer required skim passes.

High Speed Automatic Wire Threader

The new high speed, automatic, annealing wire threader

improves wire straightness which increases the AWT repeatability

especially at larger Z heights. With the annealing process, the

wire is heated, stretched and cut to a sharp point resulting in

a smaller required wire guide clearance resulting in improved

part accuracy. Since the annealing AWT can thread in the

submerged mode, the worktank does not have to be drained when

wire threading. The Z axis position will automatically set the

dielectric fluid for the operator.

Standard Technology

Standard wire EDM technology includes the high speed

electrolysis-free circuitthat eliminates workpiece oxidation

and improves part straightness.The corner control circuit

improves corner accuracy. The energy saving circuit saves on

energy cost by recycling unused discharges that were not used in

the discharge process. The AG400L is designed with Sodick's new

Environment Adaptation System. Machine temperature is

stabilized by circulating the air inside the column. Heat

insulation material covers the entire column and prevents the

outside air from affecting the temperature inside the column

thus improving the machine�s thermal stability. A dielectric

chiller and transformerare also included.