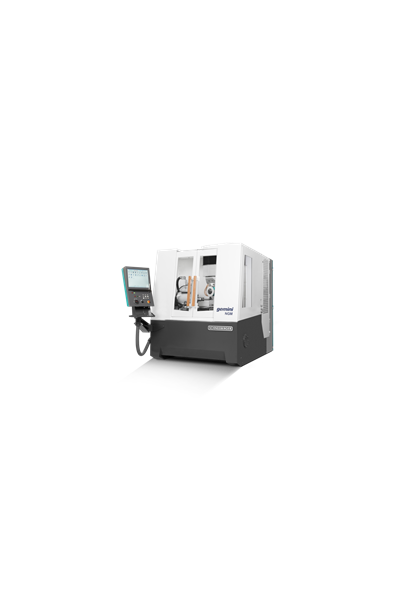

Schneeberger sirius NGS

Dynamic grinding with high precision: Perfect kinematic design for grinding profile inserts and other high-precision tools. 6-axis CNC grinding machine with high performance and autonomy for the serial production of turning inserts and profile tools as well as the grinding of high-precision components. ThesiriusNGSis the 6-axis CNC grinding machine with linear and direct drive motors for the serial production of all types of profiles. Grinding wheels up to 300 mm in diameter and the associated process stability meet the highest demands for precision. Dressing and in-process measurement guarantee consistent precision, increase the flexibility and enable a high degree of autonomy. The 6-axis robot loads complex parts to be ground on multiple sides into the specific clamping system and can simultaneously carry out additional tasks such as laser marking while grinding the next tool time. Numerous accessories for the application spectrum and increased productivity: 6-axis robot for lo ading workpieces with capacity for 2, 4, or 10 pallets Laser marking of the workpieces Grinding wheel loader with 7 grinding wheel packages incl. coolant nozzles Dressing unit for dressing profiles and sharpening Hydraulic tailstock Hydraulic steady rest Collet chucks, turning inserts holder Coolant filtration system Exhaust air filter CO2 extinguishing system

| Machine Operation: | CNC |

|---|---|

| Grinder Type: | Profile |

| CNC Model: | Fanuc 31i-B5 |

| Grinding Wheel: |

|

||||

|---|---|---|---|---|---|

| Wheel Head: |

|

| Longitudinal: | 15.750" 400.000mm |

|---|---|

| Cross: | 13.780" 350.000mm |

| Vertical: | 11.020" 280.000mm |

IS THIS YOUR COMPANY?