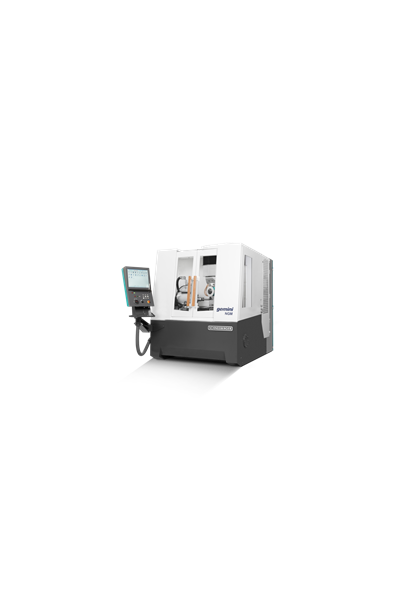

Schneeberger norma NGC

Universal and compact 5-axis CNC tool grinding machine designed for the production and regrinding of end mills, drills, profile tools and the servicing of gear cutting tools. ThenormaNGCis the universal 5-axis CNC tool grinding machine for the production and regrinding of cutting tools. Complete processing around OD and face, up to 300 mm cutting length, diameter up to 400 mm, maximum workpiece length that can be clamped 500 mm. Cutting tools such as end mills, ball nose cutters for mold making, high-performance drills, reamers, profile end mills, indexable profile inserts in HSS, carbide gear cutting tools. There are specific software, grinding processes and clamping systems for regrinding gear cutting tools, end mills, pinion cutters and bevel gear cutters. Production grinding of knives for the paper, food and plastics industries. Wheel-shaped workpieces with special clamping and automatic loading. Accessories for individual expansion of the application spectrum and for increa sing productivity. Numerous accessories to expand the application range and productivity of the machine. Workpiece loader Grinding wheel pack loader Measurement system in all axes Manual or hydraulic tailstock Manual, hydraulic or CNC controlled steady rest, following the grinding point Collet system, clamping mandrel, indexable tool holder Coolant filtration system Exhaust air filter CO2 extinguishing system

| Machine Operation: | CNC |

|---|---|

| Grinder Type: | Tool & Cutter |

| CNC Model: | Fanuc 31i-B5 |

| Grinding Length: | 11.800" 300.000mm |

|---|---|

| OD Max Grinding Diameter(s): | 15.750" 400.000mm |

| Grinding Wheel: |

|

||||||

|---|---|---|---|---|---|---|---|

| Wheel Head: |

|

| Longitudinal: | 18.500" 470.000mm |

|---|---|

| Cross: | 15.350" 390.000mm |

| Vertical: | 12.800" 325.000mm |

IS THIS YOUR COMPANY?