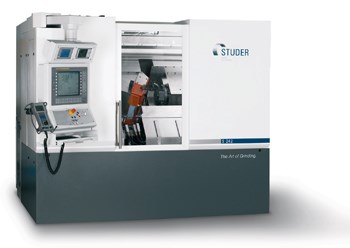

Studer S12

Studer S12 External Cylindrical Grinder with Internal Grinding Function Studer S12 --> CNC External ProductionGrinder The basic concept and target of theStuder S12 Production ID/OD grinder was to create a highprecision machine without compromise. The heart of the machine is ahigh precision positionable linear motors completely new, patented drive/guide system b. The extremely rigid slides with hydrostatic bearings are magnetically pre-tensioned. The in-feed movement can be programmed in 10-nanometer steps. Precision: Axis movements in 10-Nanometer Stepps thanks to hydrostatic guideways and linear motor technology. Dynamics: infeed speed 30 m/min, Axis-acceleration up to 3 m/s2 Flexibility: Various wheel dressing concepts, Internal grinding spindle on a separate cross-slide, automatic handling Features: X axis 0 or 30 deg X axis: Hydrostatic with Linear motor or linear guide ways with re-circulating ball screws Z axis : Hydrostatic with Linear Motor or patented guide way with knob-structure and re-circulating ball screws C axis for workhead Internal grinding unit with separate cross slide for simultaneous grinding of Internal/External diameters Application specific Workheads (Hydrostatic, Motor spindle) Additional NC-Axis for the profiling of the grinding wheel Full enclosure with new door concept for optimal accessibility Machine base made of Granitan S103 mineral casting Large range of accessories Simplified programming with StuderWIN and Siemens 840D hardware Programming Software StuderGRIND for offline programming Standardised interfaces for loader and peripheral devices Specifications: Grinding length 150mm / 5.10in Center height 175mm / 6.89in Workpiece weight 30kg / 66.14lbs. Spindle drive 7.5-12.5kw / 4 hp Grinding wheel dimensions 500x80mm 19.68 x 3.14in

| Machine Operation: | CNC |

|---|---|

| Grinder Type: | Cylindrical-ID, Cylindrical-OD, Cylindrical-Uni, Profile |

| CNC Model: | Siemens 840D |

| Grinding Length: | 5.910" 150.000mm |

|---|---|

| OD Max Grinding Diameter(s): | 13.780" 350.000mm |

| ID Max Grinding Diameter(s): | 3.940" 100.000mm |

| Grinding Wheel: |

|

||||||

|---|---|---|---|---|---|---|---|

| Wheel Head: |

|

||||||

| Workhead: |

|

| Longitudinal: | 13.780" 350.000mm |

|---|---|

| Cross: | 11.810" 300.000mm |

IS THIS YOUR COMPANY?