Chiron Series 28

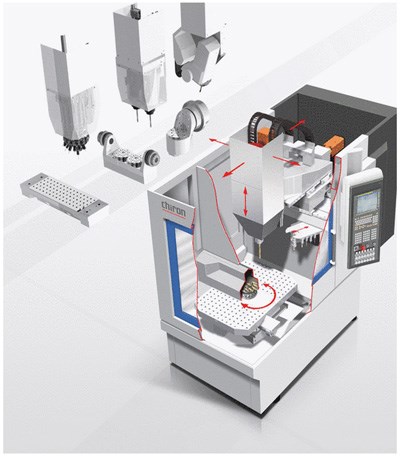

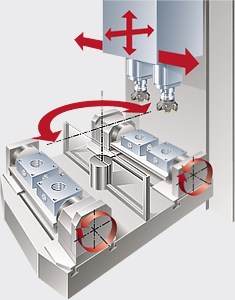

Complex hybrid drives, lightweight constructions for chassis and structural components, battery trays, more efficient internal combustion engines: The 28 Series is the convincing response to the changes in the manufacturing processes and your more stringent requirements for machining technology. With a spindle distance of 1,200 mm, the double spindles are ideal for 5-axis machining of challenging, large-scale workpieces: productive, dynamic, and precise. The compact, flexible machine layout, spindles that can be moved independently on the X and Y axes, simple automation, optimum access to the working area, and operation and loading on separate sides are all further benefits for your day-to-day production process. There's also the layout of the machining center such as the DZ 28 S five axis for direct loading or the DZ 28 P five axis with pallet changer for high quantities and short cycle times.

| Machine Type: | Machining Center |

|---|---|

| Num. of Axes: | 3 |

| Operation Type: | CNC |

| CNC Brand: | Fanuc |

| CNC Brand Opt: | Siemens |

| Support Index Table: | Optional |

|---|---|

| Support Rotary Table: | Optional |

| Num. Main Spindles: | 2 |

|---|---|

| Direction: | Vertical |

| Taper: | HSK 63A |

| Top RPM: | 20,000 |

| Top RPM Opt: | 12,500 |

| U Axis: | None |

| Tool Carrier: | ATC |

|---|---|

| Num. Tools: | 60 |

| Num. Tools Opt: | 90 |

| Tool Change Time (sec): | 2.00 |

| Tool Change Chip Time (sec): | 2.70 |

| Pallet Changer Available: | Optional |

| Num. Pallets: | 4 |

| Num. Axes: | 3 | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| U Axis: | None | ||||||||||||||||||

|

|||||||||||||||||||

IS THIS YOUR COMPANY?