Chiron MT 724 2C

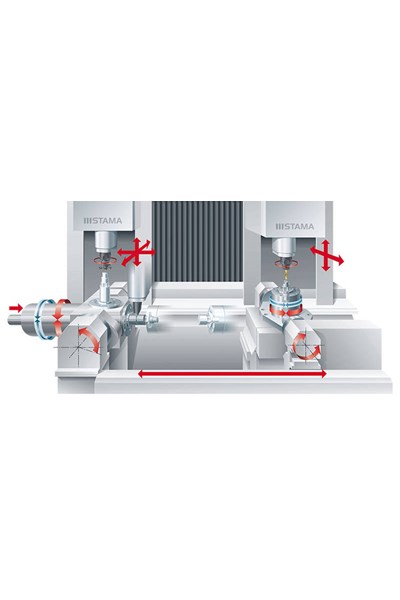

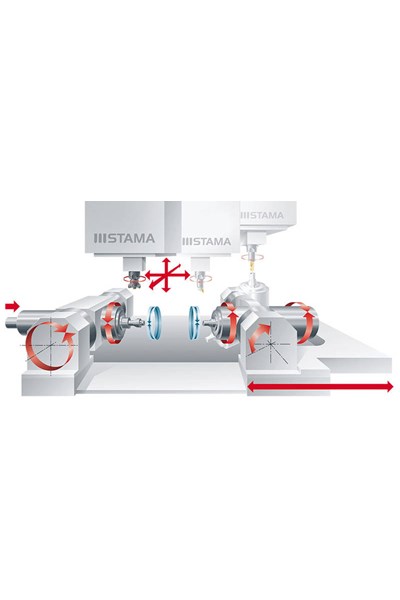

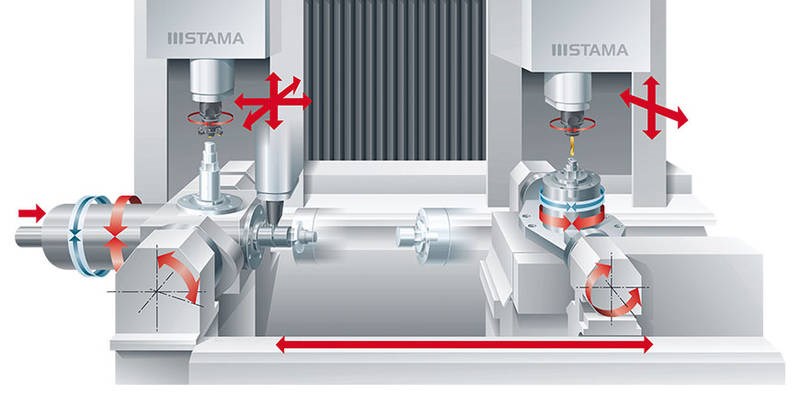

The MT 2C works with two independent operator platforms on a base frame. In the left work space, sides 1–5 of the workpiece are machined; and in the right, sides 2–6. In parallel, 5-axis (also simultaneously), each with one turning and one milling spindle in use. Two work spaces, two operator platforms and built according to the PEPS®principle: for high output within a small footprint.

| Machine Style(s): | Bar, Chucker, Universal |

|---|---|

| Spindle Direction: | Horizontal |

| Operation Type: | CNC |

| CNC Type: | Fanuc 31 i-A5 |

| CNC Type Opt: | Siemens 840D sl |

| Main Spindle Turning Diameter Max: | 2.560" |

|---|---|

| Main Spindle Turning Length Max: | 4.720" |

| Main Spindle Chuck Diameter: | 4.000" |

| Main Spindle Bar Diameter Max: | 2.550" |

| Tail Stock Quill And Body: | None |

| Num. Main Spindles: | 2 | |||||

|---|---|---|---|---|---|---|

| Main Spindle 1: |

|

|||||

| Main Spindle 2: |

|

| Primary Tool Carrier: | ATC | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Max Tools: |

|

||||||||

| Rotary Tool: |

|

||||||||

| Second Tool Carrier: | ATC | ||||||||

| Max Tools: |

|

||||||||

| Rotary Tool: |

|

||||||||

| Num. Simultaneous Cutting Tools: | 2 | ||||||||

| Secondary Mill/Drill Function: |

|

| Number Of Axes: | 9 | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|||||||||||||||||||

IS THIS YOUR COMPANY?