Makino EDNC6

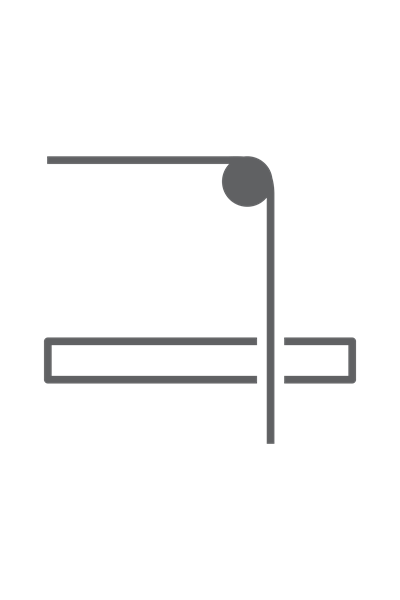

The EDNC6 machine provides similar high performance as the EDAF-Series, but with larger X/Y/Z strokes and larger work tank. The EDNC6 machine utilizes a stationary work table design for improved precision, and also incorporates the dielectric reservoir into the base casting to improve thermal stability and to minimize floor space requirements. The optional high speed HS-Rib Z-Axis provides jump speeds of up to 20m/min with 1.5G acceleration, and when coupled with Makino’s advanced HyperCut and SuperSpark™ IV technologies, ensures optimal productivity. The capability and ease of the Hyper-i control further enhances operators capabilities with integrated on-board digital manuals, intelligent E-Tech Doctor help functions and e-learning training system that can be quickly accessed for operator convenience. The standard EDNC6 configuration utilizes a three-sided programmable rise-and-fall work tank that accommodates work piece sizes up to 39” x 29” (1,000mm x 750mm), but the EDNC6 is also available in a Wide Tank version that supports larger-sized parts up to 55” x 35” (1,400mm x 900mm) and utilizes a programmable rise-and-fall front door.

| Machine Type: | CNC Sinker |

|---|---|

| Frame Type: | Bridge |

| Submersible: | Standard |

| Table (L x D): | 31.500" x 21.700" |

|---|---|

| Worktank (L x D x H): | 43.300" x 29.500" x 17.700" |

| Auto Electrode Changer: | Optional |

|---|

| Number Of Axes: | 3 |

|---|---|

| X Axis Travel: | 25.600" |

| Y Axis Travel: | 17.700" |

| Z Axis Travel: | 13.800" |

| C Axis Available: | Standard |

IS THIS YOUR COMPANY?